Services

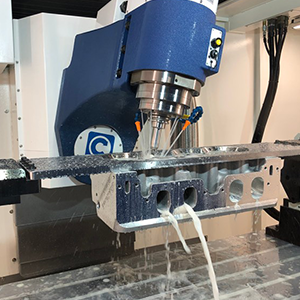

Twisted CNC Repair provides regular maintenance on CNC equipment to prevent costly downtimes from unexpected equipment failures. With the right planning and scheduling, we can provide a maintenance strategy that services your equipment before a problem occurs.

Utilizing our extensive experience in the industry, we exceed customer expectations by providing the highest quality:

Preventative Maintenance

Machine Cleaning

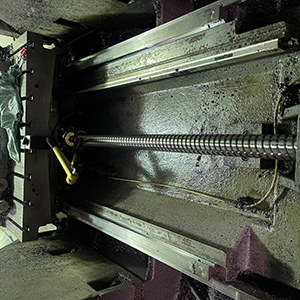

Ballscew Replacement

Maintenance Training

Tool Changer Alignment

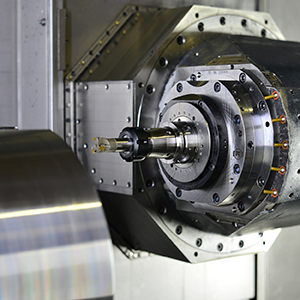

Spindle Changes

Software Updates

Geometry Inspections

Kinematic Adjustments

Machine Installations

Troubleshooting

Custom Maintenance Plans

Machine Relocation

(excluding rigging)

The Twisted CNC Repair Advantage

We specialize in providing bottom-line results for our customers. Our cost-effective and innovative solutions are guaranteed to reduce your downtime and increase the overall productivity of your machinery. Throughout the life of the project, we keep the lines of communication open so you stay connected and we better understand your needs.

We also have experience working on Siemens, Heidenhain, Fanuc, and Mitsubishi controls. No matter the challenge, Twisted CNC Repair can deliver the solution!

Why CNC Maintenance is Crucial?

CNC machines that are down and not producing can cost machine shops thousands of dollars in unmet shipments and lost customers, CNC machines should have scheduled inspections and preventative measures that reduce production delays caused by breakdowns of machinery.

Quality

Twisted CNC Repair continuously works to improve processes to deliver quality products and services, while continuously improving our processes and services

Our Customers

If you are in the aerospace, tool & die, mold making, job shops, or any other industry that uses CNC machining equipment, we are your industry-leading provider.

Equipment

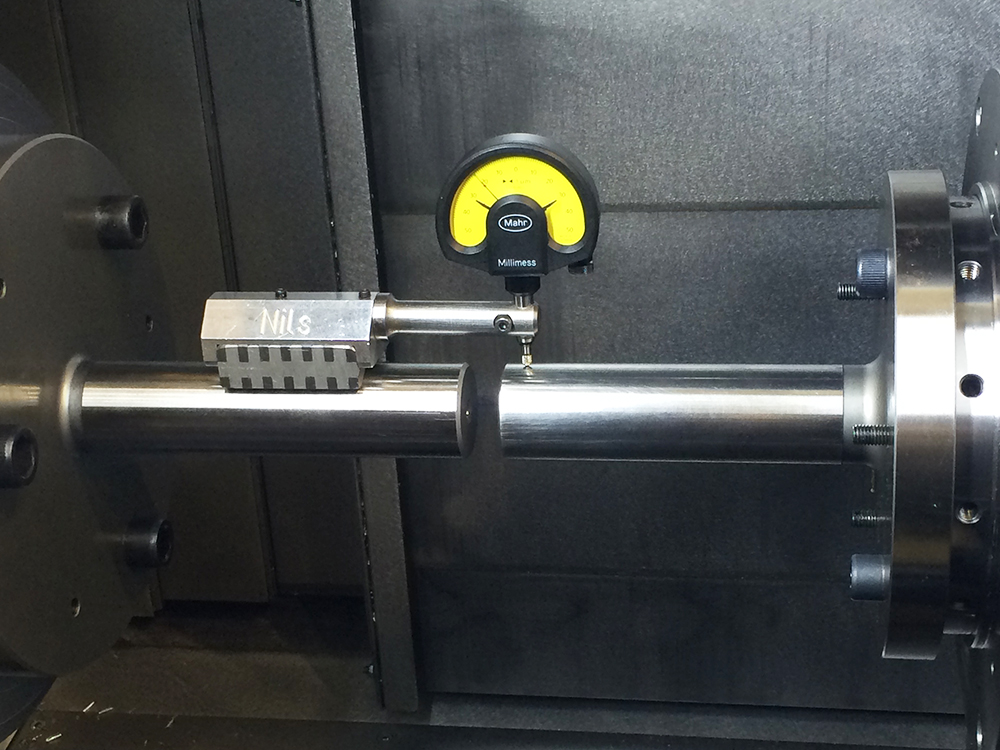

Twisted CNC Repair invests in the latest equipment and technology to provide our customers with the highest quality components, parts, and services. Our facility is equipped with precision test bars, PWM9, ATC alignment tools, precision ground granite square, clamp force guage, precision digital levels and a kinemtic tooling ball to meet the challenges of our customers.

Frequently Asked Questions

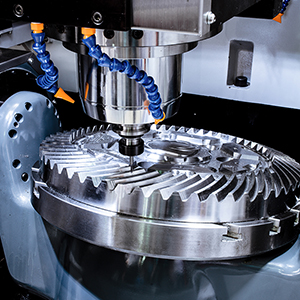

CNC machine tools and equipment include but are not limited to three-dimensional cutting tools, lathes, routers, mills, and grinders.

Preventive maintenance (PM) is regularly scheduled intervals in which you take the machine out of service to change or verify fluids, inspect certain wear items, and assess the overall health of the machine. The goal is to be proactive with repairs and adjustments, instead of reactive which can be much more costly.

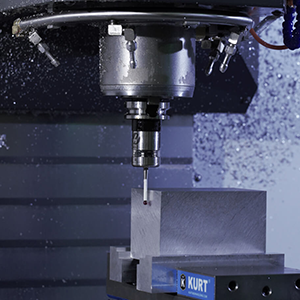

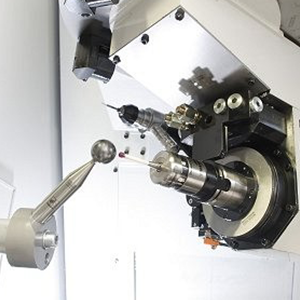

Tool changer alignment gauges are used to test automatic tool changer positioning between the gripper arm, magazine, tool holder, and the spindle.

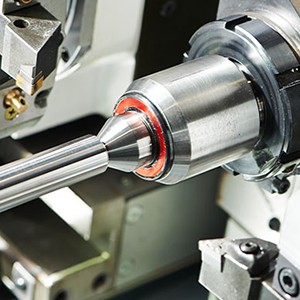

Spindles rotate on the axis operated from the CNC controller. The spindle is a crucial part of a CNC machining center. The shape of the spindle determines the speed and cutting force. A machine tool can have numerous spindles, the largest is called the main spindle.

Geometry Inspections are used to detects flaws in model geometry and it provide feedback for resolving the errors.

Kinematics is a two-way function to transform from Cartesian space to joint space.

Static geometries are measured when an axis of the machine moves from one set point to another using an external device such as; mag base and indicator, precision test mandrel, precision master square, or laser. Static geometries can be adjusted mechanically or be compensated volumetrically.

Dynamic geometries can be identified as the accuracy of the axes when they are in motion or when the machine is machining a part. These are generally measured using a CMM.

Static geometries can be adjusted mechanically or through volumetric compensation on the control. Dynamic geometries can be adjusted by servo tuning. The first step to improving machine accuracy is making sure the machine is properly leveled and has tight static geometries.

One of the main reasons to perform regularly scheduled preventative Maintenace is to reduce unplanned downtime. Machine breakdowns are inevitable, but to what degree can be determined by how you care for your equipment. Let Twisted CNC Repair take the guesswork out of preventative maintenance. Preventative maintenance is not as simple as changing a few oils and marking some boxes on a basic checklist. Train professionals have an eye for not so noticeable items as well as properly inspecting crucial components that may have pre mature wear. Don’t miss a deadline or risk a major contract getting away due to machine neglect.

GET THE EQUIPMENT TO GET YOUR JOB DONE

Our single-minded goal is to deliver the products, services and solutions that help you be better at what you do.