bottom-line results of customers

on CNC equipment to prevent costly downtimes from

unexpected equipment failures.

Twisted CNC Repair was founded in 2021 by Joe Christensen in Gilberts, Illinois.

With extensive overseas factory training, 8+ years working for OEMS, and 16+ years of industry experience, Joe delivers innovative solutions that reduce downtime and increase productivity of a facility’s CNC equipment. With a focus on customer service, Twisted CNC Machine is your best choice in the industry.

What We Do

Utilizing our immense factory training, extensive industry experience, and the latest in equipment, we provide the standard in troubleshooting, repairs, maintenance and much more for your machine tools. We strive to provide industry leading customer service to large corporations with multiple machines, all the way down the small business owner with 1 piece of equipment.

Our Services

Twisted CNC Repair provides regular maintenance on CNC equipment to prevent costly downtimes from unexpected equipment failures. With the right planning and scheduling, we can provide a maintenance strategy that services your equipment before a problem occurs.

Why Choose Twisted CNC Repair?

Twisted CNC Repair delivers bottom-line results of customers. When you work with us you can always expect

- Open communication and collaboration throughout the project

- Innovative and cost-effective solutions designed to increase productivity and reduce downtime

- A profound dedication to exceeding customer expectations

- A close and personal interaction with people who know and understand the demands of the industry

The Twisted CNC Repair Advantage

We specialize in providing bottom-line results for our customers. Our cost-effective and innovative solutions are guaranteed to reduce your downtime and increase the overall productivity of your machinery. Throughout the life of the project, we keep the lines of communication open so you stay connected and we better understand your needs.

We also have experience working on Siemens, Heidenhain, Fanuc, and Mitsubishi controls. No matter the challenge, Twisted CNC Repair can deliver the solution!

Equipment

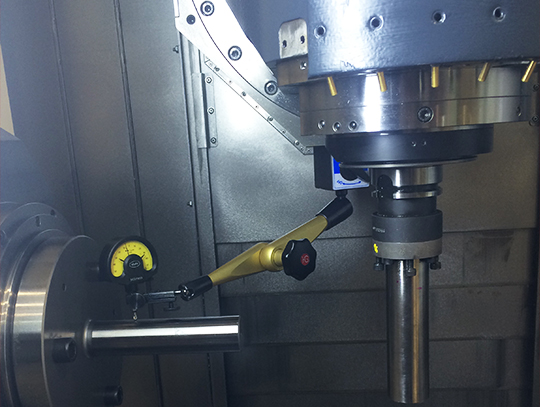

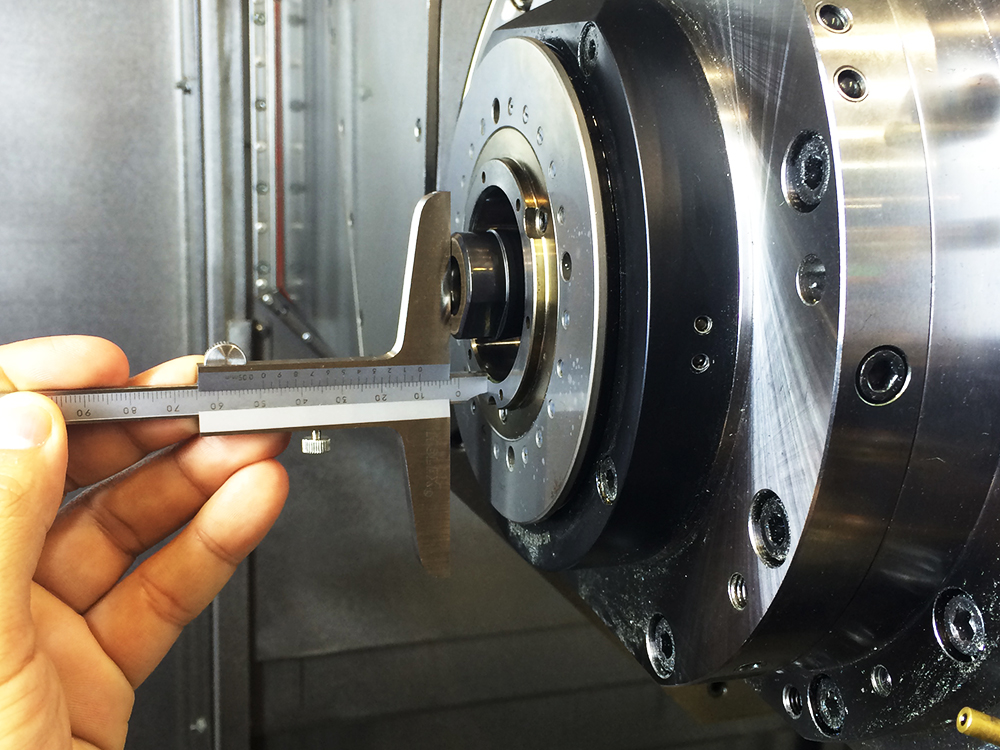

Twisted CNC Repair invests in the latest equipment and technology to provide our customers with the highest quality components, parts, and services. Our facility is equipped with precision test bars, PWM9, ATC alignment tools, precision ground granite square, clamp force guage, precision digital levels and a kinemtic tooling ball to meet the challenges of our customers.

Frequently Asked Questions

CNC machine tools and equipment include but are not limited to three-dimensional cutting tools, lathes, routers, mills, and grinders.

Preventive maintenance (PM) is regularly scheduled intervals in which you take the machine out of service to change or verify fluids, inspect certain wear items, and assess the overall health of the machine. The goal is to be proactive with repairs and adjustments, instead of reactive which can be much more costly.

Tool changer alignment gauges are used to test automatic tool changer positioning between the gripper arm, magazine, tool holder, and the spindle.

GET THE EQUIPMENT TO GET YOUR JOB DONE

Our single-minded goal is to deliver the products, services and solutions that help you be better at what you do.